Liquid cooled Data Center

As data centers adopt advanced cooling technologies such as direct-to-chip cooling and immersion cooling, liquid leak detection becomes crucial. Liquid cooling offers significant benefits in terms of efficiency and thermal management, but it also introduces the risk of leaks, which could lead to equipment failure, downtime, or even costly damages. To ensure the reliability and safety of operations, choosing the right leak detection system is key.

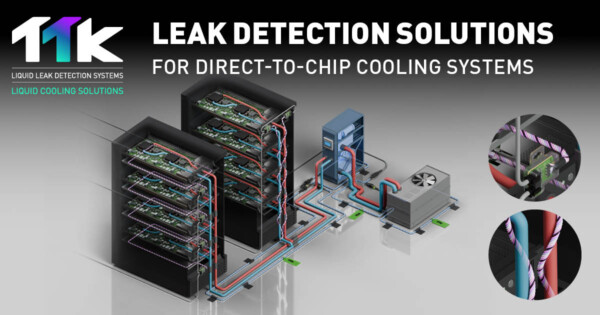

Direct-to-Chip Cooling (or Direct Cooling)

In direct-to-chip liquid cooling, cold liquid is directly circulated through tubes and cold plates attached to the most heat-sensitive components, such as CPUs, GPUs, and memory modules. Heat is transferred from the chips to the cold plates and then to the liquid, which is pumped away to be cooled elsewhere.

This technique is ideal for high-density servers and racks with powerful processing units that generate a lot of heat.

TTK Leak Detection Solutions for Direct-to-Chip Cooling

In direct-to-chip cooling, where liquid coolants are circulated through cold plates attached to servers' processors, TTK provides:

- Server-level monitoring to detect leaks near critical components.

- In-rack and above-rack detection, ensuring coverage of all critical areas inside and around the server rack.

- Pinpoint leak location for quick response and minimal downtime.

Advantages of TTK Solutions for Liquid-Cooled Data Centers

Liquid leak detection is vital to liquid-cooled data centres' safe and efficient operation. Even a small leak could lead to significant financial and operational losses without a reliable detection system. TTK provides:

- Comprehensive protection for both immersion cooling and direct-to-chip cooling setups.

- Specialized sensing cables for all types of liquids.

- Real-time monitoring, with fast and precise leak detection, ensuring minimal disruption.

- Tailored made leak detection systems to meet the specific needs.

- Long Product Life & Low Constraint of Maintenance